| |

|

管件产品生产设备 Pipe Fittings Produce Machine |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

全自动型液压中频弯管机设有机械部分和电器控制部分。 中频弯管机机械部分设有4大机构分别为动力源机构、夹紧固定机构、弯管弯曲半径调节机械、推进机构。

中频弯管机电器部分由2大系统组成分别为加热系统和PLC控制系统 。 Automatic type hydraulic if pipe bender is equipped with mechanical part and electric controlling part. Mechanical part has four institutions: Power supply mechanism, clamp fixed institution, bend radius adjusting mechanism, feed mechanism.

Electrical part of If pipe bending

machine consists of two systems: Heating system and PLC control system.

The Siemens S7-200, using the industrial computer or touch screen , We

developed a set of automatic control system from year 1994 according

to the bending process : - Put the required bend geometry size, bending

radius, bend Angle and raw material Numbers, material, heating required

temperature and a series of data into the computer, let the computer

has automatic tracking control according to those data, complete the

tube bending process . |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

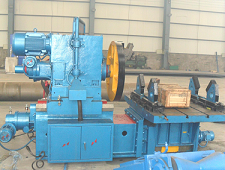

| 弯头机组成部分:弯头推制机主机、液压泵站、操作台、电机控制柜、中频电源、补偿电容器、水电缆、中频线圈调整架、电抗器。 弯头机可推制最大口径为Φ1420mm的弯头。 弯头机设备优点: 1.弯头机加热电源部分——恒功率输出。采用独有的稳压技术,即使进线电压波动10%,仍能保持中频输出功率稳定。节能环保、噪音小,污染小。 2.弯头机采用液压自动上料机构。 3.弯头机闸门采用液压开闭。 4.弯头机线圈支架上下,前后,摆动采用电机调整,操作更安全。 5.弯头机根据设备需要采用二支或四支油缸推制,设备运行更平稳。 Constituent parts of elbow formingmachine: Main machine, hydraulic powerstation, operation desk, motor control cabinet,medium frequency power supply, compensatingcapacitor, water cable, adjustable holder ofinduction coil and reactor. The elbow forming machine canmake elbow size upto Φ1420mm . The elbow forming machine hasfollowing advantages: 1. The elbow formingmachine heating powersection---Constant power output. Using theunique stabilized voltage technology, eventhough the input voltage has 10% of fluctuation,can still keep the stability of intermediatefrequency output power. Energy saving andenvironmental protection, noise and pollution issmall. 2. The elbow formingmachine adopts hydraulic automaticfeeding mechanism. 3. The elbow formingmachine lock gate adopts hydraulic openand close. 4. The elbow formingmachine induction coil holder up anddown, front and back actions adjustable bymotor, operating is safer. 5. The elbow formingmachine uses 2 cylinders

or 4 cylindersaccording to the requirement of the machine,running more

smoothly. |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

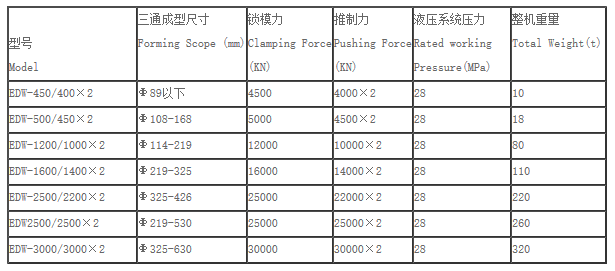

| 冷拔三通机 Cold Draw Tee Machine | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

EDW系列冷挤三通机适用于Φ21-426mm的不锈钢及碳钢三通管件。

EDW Series of cold extrusion teeforming

machine are suitable for carbon andstainless steel pipe fitting teeforming(Φ21-630mm). |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

扩管机是针对大直径无缝钢管生产量不足和规格不全而设计的。该设备为双油缸或四油缸平行均速推制机,泵站阀台采用集成形式。按扩制钢管的外径及长度,设置中频加热电源的功率、油缸的推力及行程。 The expanding machine isdesigned due to the insufficiency of largediameter seamless steel tube production andspecification. It’s a two oil cylinder or fouroil cylinder parallel uniform velocity pushingmachine, pump station valve table adoptsintegrated form. Setting the power of mediumfrequency heating power supply, force and strokeof oil cylinder according to the outer diameterand length of the pipe. The expanding machine hasfollowing parts: Main machine, automatic feedingand unloading material system, hydraulic pumpstation, operation desk, motor control cabinet,medium frequency power supply, compensatingcapacitor, water cable, adjustable holder ofinduction coil and reactor. The expanding machinemaximum expanding range: pipe diameter

Φ 1520mm, wall thickness 120 mm. |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

压力机的工作环境: 1、温度:0℃ ~40℃. 2、湿度:相对湿度90%以下。 3、电压:380V(-15%、+15%)、50Hz。 压力机用途:适用范围:机器适用于可塑性材料的压制工艺,如翻边、薄板拉伸、弯曲等,也可从事校正、压装、冷挤、塑料制品及粉末制品的压制成型工艺。 压力机主要特点:1、压力机结构采用计算机优化设计、结构简单、经济实用。 2、压力机液压控制采用集成系统,动作可靠、使用寿命长、液压冲击小、并减少连接管路与泄漏点,液压集成系统采用独立控制单元。 3、压力机独立的电气控制系统,工作可靠、动作直观、维修方便。范围:最大能生产2500T压力机。 另外我厂生产的压力机远销印度、俄罗斯等国家. 1,Hydraulic presses machine tool workingenvironment: 1. Temperature: 0 ℃ to 40 ℃. 2. Humidity: relative humiditybelow 90%. 3. Voltage: 380 v (15% and +15%), 50 Hz. Application: Used for pressingtechnology of plasticity material, Such asflanging, sheet tensile, bending, etc, can alsoused for correct, pressing, cold extrusion andpressure molding process of plastic products andthe powder product. Main features of Hydraulicpresses machine : 1. Structure of hydraulicpresses machine adopts the computeroptimization design, the structure is simple,economical and practical. 2. Hydraulic control of hydraulic presses machine using integratedsystem, reliable operation, long service life,hydraulic impact is small, and reduce theconnecting line and leakage point, hydraulicintegrated system uses independent control unit. 3. Independent electrical controlsystem of hydraulic presses machine , reliablework, action intuitive, convenient maintenance.Scope of production: Maximum can produce 2500Thydraulic press. Our hydraulic presses areexported to India, Russia and

other countries. |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 坡口机 Bevel Machine |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

本机床适用于电站、石油、化工、造船等行业中管件制造、管道安装单位使用;是管件制作和管道施工焊接前管端坡口加工的关键设备。本机床由动力头、刀盘结构、床身结构、夹具平台结构、电气控制系统等五大部件组成。

The machine is suitable forcompanies who worked on pipe fitting forming andpipe installation in power plant, petroleumindustry, chemical industry, shipbuildingindustry, etc. It's a key machine for pipefitting forming and pipe end beveling beforewelded in pipeline construction. The machineconsists of power head, cutter structure, bedstructure, fixture platform structure,electrical control system, etc.

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

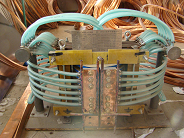

我们的KGPS系列中频感应线圈供应适用于冶炼,虽然热,热膨胀, Our KGPS Series ofintermediate Frequency induction coil Supply suit for smelting,though hot ,hot expansion,

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Hydraulic press Machine |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Pipe automatic cutting machine |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Abrasive Tool | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||