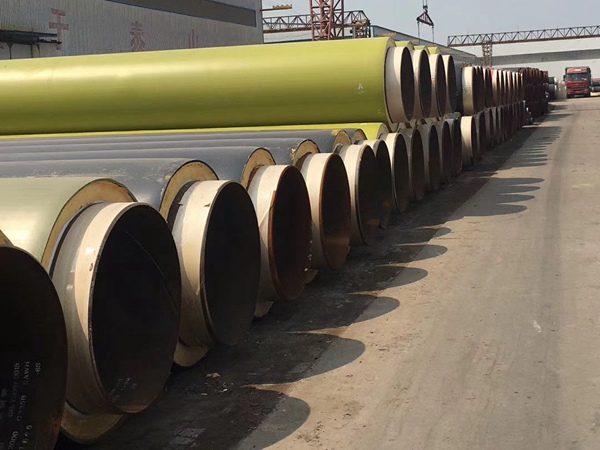

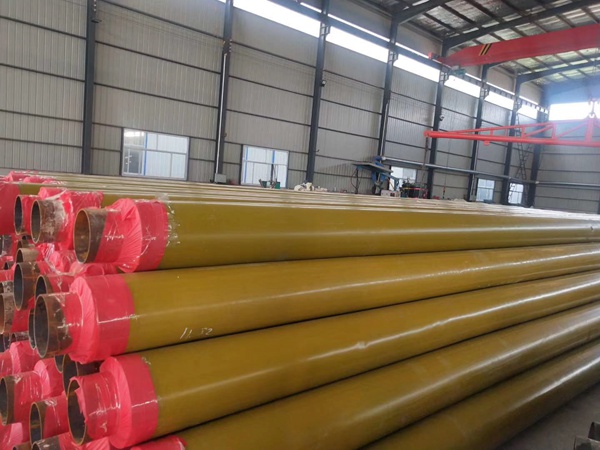

| 管道及管件保温 Pipe Lines and

Fittings Insulation |

|

|

|

|

|

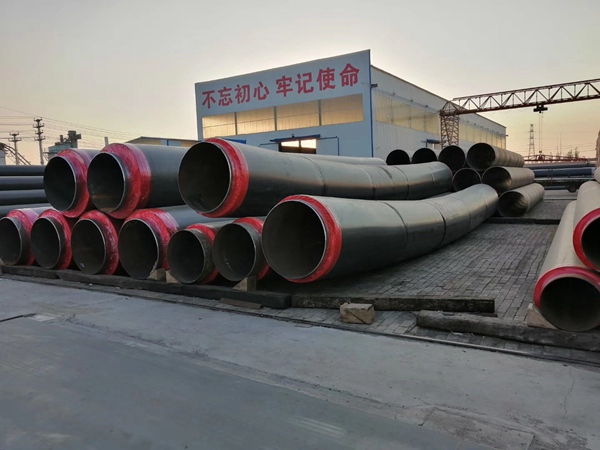

保温弯头

Elbow

Insulation |

|

|

|

|

|

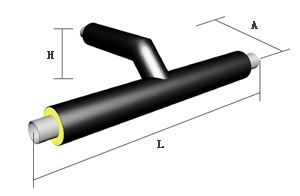

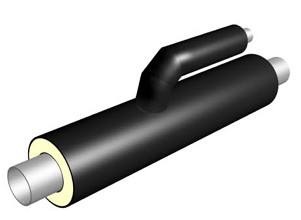

Spanning Tee Insulation |

|

Parallel Tee Insulation |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 聚氨酯保温

1、介质传递的重要媒介

作为管道,其功能就是负担输运相关流体、气体介质,而对于我国北方很多的省份人们来说,供给暖气就是很重要的一项民用输运工程,暖气水流经过产生端口向千家万户的用户家中输送,这个时候就需要有质量好、性能良好的管道来进行中间过程的输送。

2、能量保持

由于相关带有一定温度的介质在传输过程中,难免与外界的常温环境产生热量交换,而热量交换的过程,一方面会减少温度介质作用的有效使用率,从而花费更多的能源而获得过少的效益,另一方面可能影响传输物质的形态和压强变化,产生相应的工程问题,而聚氨酯保温管道可以有效的保证这一过程中的能量耗散量。

3、结构支撑和保持

无论是埋设在土壤中的管道还是暴露在空气环境中的管道,都必须保证管道系统的稳定性,否则会造成多次更换引起工程成本的增加以及停供给损失,良好的结构支撑可以保证材料运输过程的可持续性。

聚氨酯保温管道的现场施工条件要求

聚氨酯保温管道的保温性能好,抗腐蚀性好,工程造价低等,因为有着这样的优势,所以被广泛应用到各个领域的工程建设,不管是化工,石油,还是供水供热供气,都发挥了比普通的管道更好的作用,而且聚氨酯保温管道由于其优势,可以减少施工时间,削减施工量,这样就减少了对施工附近居民的打扰,那对于聚氨酯保温管道的现场施工有什么条件要求呢?

一、工作人员

预制直埋管道的安装施工,必须经过专业培训,持证上岗,他们不能是普通的建筑工人,不专业会导致安装过程中的错误。

二、材料

聚氨酯保温管道的材料必须有产品合格证并通过质量检验,以保证聚氨酯保温管道能发挥其应有的优势和特点。

三、干燥的环境

聚氨酯保温管的材料虽然吸水率低,但是也不是不吸水,所以在施工过程中,一定要设置排水管,使水尽快流失,聚氨酯保温管不能浸泡,会大大降低其效率。

四、现场

施工现场不应在夜间无人值守,应派专人24小时值班,观察管道的详情,以免管道被浸泡,影响施工过程和使用效果。 |

Polyurethane insulation

1. An important medium for medium transmission

As a pipeline, its function is to transport related fluids and

gaseous media. For people in many northern provinces of my country,

supplying heating is a very important civil transportation project.

The heating water flows through the generation port to the users

of thousands of households For home transportation, at this time,

a pipeline with good quality and good performance is required

to carry out the transportation in the intermediate process.

2. Energy maintenance

Since the relevant medium with a certain temperature will inevitably

exchange heat with the outside normal temperature environment

during the transmission process, and the process of heat exchange

will reduce the effective utilization rate of the temperature

medium on the one hand, and thus spend more energy to obtain overheating.

On the other hand, it may affect the shape and pressure changes

of the transported substances, resulting in corresponding engineering

problems, and the polyurethane thermal insulation pipeline can

effectively ensure the energy dissipation in this process.

3. Structural support and maintenance

Whether it is a pipeline buried in the soil or a pipeline exposed

to the air environment, the stability of the pipeline system must

be ensured, otherwise it will cause multiple replacements, resulting

in an increase in engineering costs and loss of supply, and good

structural support can ensure material transportation. Sustainability

of the process.

Requirements for on-site construction conditions of polyurethane

thermal insulation pipes

Polyurethane thermal insulation pipeline has good thermal insulation

performance, good corrosion resistance, low engineering cost,

etc. Because of such advantages, it is widely used in engineering

construction in various fields, whether it is chemical, petroleum,

or water supply, heating and gas supply. It has a better effect

than ordinary pipes, and because of its advantages, polyurethane

insulation pipes can reduce construction time and construction

volume, thus reducing the disturbance to residents near the construction.

What are the requirements for the on-site construction of polyurethane

insulation pipes Woolen cloth?

1. Staff

The installation and construction of prefabricated directly buried

pipelines must undergo professional training and work with certificates.

They cannot be ordinary construction workers. Unprofessionalism

will lead to errors in the installation process.

2. Materials

The material of the polyurethane thermal insulation pipe must

have a product certificate and pass the quality inspection to

ensure that the polyurethane thermal insulation pipeline can play

its due advantages and characteristics.

3. Dry environment

Although the material of the polyurethane insulation pipe has

a low water absorption rate, it is not non-absorbent. Therefore,

during the construction process, a drainage pipe must be installed

to make the water run off as soon as possible. The polyurethane

insulation pipe cannot be soaked, which will greatly reduce its

efficiency.

4. On-site

The construction site should not be unattended at night, and special

personnel should be dispatched on duty 24 hours a day to observe

the details of the pipeline, so as to prevent the pipeline from

being soaked and affecting the construction process and use effect. |

| |

|